How Heat Resistant is Filament Strapping Tape? Essential Facts for Effective Pkg Tape Usage

How Heat Resistant is Filament Strapping Tape? Essential Facts for Effective Pkg Tape Usage

Blog Article

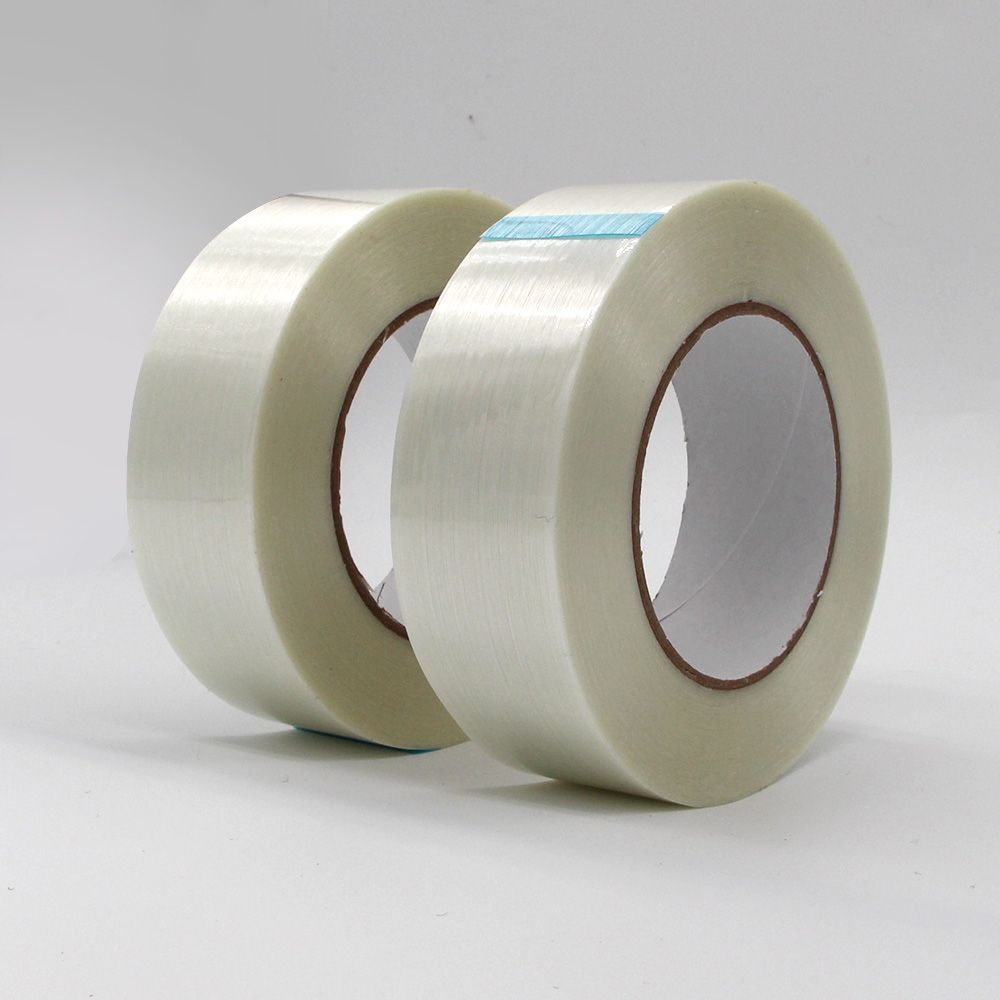

Filament strapping tape is a staple in various industries, prized for its strength, adaptability, and multifunctionality. Typically constructed from a robust plastic film, often polyester, and reinforced with fiberglass filaments, this tape is designed to take on demanding tasks such as bundling, palletizing, and shipping. However, a common question surfaces: How heat resistant is filament strapping tape? Understanding its heat resistance properties is essential for selecting the right materials for specific applications, especially when working with sealing tape, packaging tapes, and other types of pkg tape.

Composition and Characteristics

The effectiveness of filament strapping tape is closely tied to its composition. The polyester backing affords it a degree of thermal resilience, but this resilience has its limits. Generally, filament tape functions well across a spectrum of temperatures, from -40°F to 200°F (-40°C to 93°C). While these temperatures are suitable for a wide range of applications, exceeding them can compromise the tape's integrity and adhesive properties.

The unique design characteristics of filament strapping tape make it suitable for critical tasks in shipping and packaging. Its strength makes it the preferred choice for tasks that involve securing heavy loads, while its flexibility allows for easy application and secure tape seals. However, when considering its performance in high-temperature environments, understanding the limits of packers tape becomes essential.

Heat Resistance Factors

Several factors contribute to the heat resistance of filament strapping tape:

Adhesive Type: The adhesive utilized in filament strapping tape significantly impacts its heat resistance. Different adhesives have varying responses to heat exposure. Some are engineered to maintain their bonding capabilities at elevated temperatures. For instance, using high-temperature adhesives can enhance the overall performance of the tape in heat-intensive applications where other packaging tapes may fail.

Environmental Conditions: The environment where the tape is used also plays a crucial role in its performance. High humidity or fluctuating temperatures can soften the adhesive more quickly than in stable environments, resulting in reduced effectiveness. Proper assessment of both temperature and humidity is necessary to ensure optimal results when using pkg tape in demanding conditions.

Duration of Exposure: The time that filament strapping tape is subjected to high temperatures is another important consideration. Short bursts of heat usually don't impact the tape significantly, but extended exposure could lead to adhesive failure. Understanding the potential duration of thermal exposure is crucial for determining whether filament strapping tape is the right choice for the job or if alternatives are warranted.

Applications and Limitations

Industries that rely heavily on filament strapping tape include logistics, manufacturing, and construction, where bundling products and securing loads is routine. This tape is celebrated for its durability, making it ideal for applications that require strength above all else. However, potential limitations must be noted, especially when dealing with high-temperature scenarios such as automotive and aerospace applications, where materials can reach extreme temperatures.

For such conditions, manufacturers typically recommend alternatives, like specially formulated high-temperature strapping tape. These products are engineered with enhanced heat tolerance, providing a safer option for critical applications that demand both strength and temperature reliability. It's essential to recognize that while filament strapping tape performs admirably in many situations, it has its boundaries.

Making Informed Choices

In summary, although filament strapping tape demonstrates a reasonable level of heat resistance for many general-purpose applications, its effectiveness begins to wane when exposed to excessive heat. Factors like adhesive type, environmental conditions, and duration of exposure must all be considered to ensure the optimal use of this versatile tool. Depending on your specific needs, alternatives designed explicitly for high-temperature resistance, such as heat-resistant packaging tapes, may be more suitable.

When working with adhesive products, the key to success lies in understanding their limitations and strengths. With this knowledge, users can make educated decisions about which materials to use, ensuring their packaging applications remain secure. Whether you are bundling materials, shipping products, or enhancing your packaging with seal with tape, knowing your options can lead to more effective outcomes and sustained integrity in your operations.

Report this page